We listened

to grandma.

We provide our customers with bespoke stirring system solutions, tailored to their specific needs and to those of their individual sectors. And we really do know what we are doing.

Innovation in motion

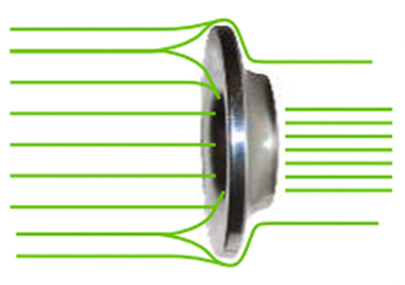

A truly thorough and energy-efficient mixing of materials: that is precisely the hallmark of our unique and patent-protected miseco® disc system, one already used by a vast number of companies both large and small right around the globe.

The efficient and energy-saving miseco® disc stirring system is a slow-running hollow body agitator with weight-efficient disc shape for stirring media ranging from liquid to highly viscous – making it suitable for a wide range of applications and industries.

The unique design of the patented miseco® disc enables it to create self-dynamic flow conditions in the vessel. This ensures that the mixing materials are stirred thoroughly within the shortest possible time without the need for recourse to baffles.

Adaptable stirring systems

Bespoke solutions

Here at miseco, we know that the wide variety of requirements of different containers, media and mixing tasks demand customised solutions. That is why we provide you with many different options for adapting this product to suit your needs.

and rotational speed

the agitators

Overall size

of the elements

Diameter

of the disc

Powerful

no problem to stir media containing solids and fibres

Fast

short mixing times because the entire volume of mixing materials is identified immediately

Robust

a balanced power-to-weight ratio for operation that protects the gear unit

Customised

can be manufactured in almost any size, and individually adaptable (for containers with a capacity of 1 litre up to tanks containing 1 million litres)

Suitable for daily use

a compact and lightweight easy-to-clean design (no blind spots for spray action)

Gentle

thanks to low, energy-saving speeds, even solids and ingredients (e.g. bits of fruit) are not destroyed by the stirring process

Economical

optimise your energy management to ISO 50001 standards – here you really can save money!

Simple

Power disruptors are not needed (including ground storage)

Slow

only gentle heating of the materials being mixed

Well thought-out

no air ingress and no foaming

Ingenious

folding agitators are available for container and drum applications. These fit through the narrowest of openings and fold open during the stirring process – can be dismantled without tools

Flexible

can be used with liquid to highly viscous media

The success story of miseco

The secret is to stir things well

Martin Hirzel, the founder and innovator behind miseco, has many years of experience in the agitator technology sector. During his time in Sales and Product Management, his efforts were dedicated consistently to continuous improvement and further development. This spirit of innovation ultimately propelled him into becoming self-employed. In 2009, he laid the foundation for his own company by developing the patented miseco® disc system stirring system.

Today, the miseco® disc stirrer system is sold in almost every European country, adapted to suit the individual requirements of its customers. Martin Hirzel is committed to having ISO-certified product quality to ensure that he is providing his customers with reliable solutions. In this way, the success story of miseco will continue being written into the future.

Certified to ISO 9001: 2015

Verifiably good.

The further development and continuous optimisation of solutions is every bit as important to us as the assured suitability for everyday use and certified quality of our products. This is the only way that we can provide you at all times with the optimum solution for your requirements. We therefore view certificates as an incentive to follow our chosen path.

Sectors

We stir the pot in all sectors.

Food Fast, gentle & resistant to sedimentation

The specific requirements of food production are all satisfied by the miseco® disc stirring system. In addition to material and processing aspects (FDA-compliant design, ground materials, etc.), the main benefits include uniform mixing at low speeds, gentle stirring and excellent transfer of heat and cold to the medium. To those, you can add dynamic flow conditions that prevent blind spots or the formation of sediment in the stirring receptacles. Therefore, the miseco® disc system is particularly suitable for products with a fruit component and for foods that need to be heated or cooled.

By the way, the oscillating product flow ensures that additives mixed from above are quickly and uniformly blended. Last but not least, the agitator and its spray heads is very easy to clean and there is not even any need for baffles.

Various agitators can be used in the food sector, including top-mounted agitators, containerised agitators and stand agitators. Just get in touch with us. We shall be delighted to advise you.

Paper A marriage of efficiency and homogeneity

In the world of the paper-making industry, the demands on agitator systems are as multi-faceted as the industry itself. Here, miseco® agitator systems specialise in keeping products with a high solids content in suspension and transforming them into homogeneous mixtures to prevent the formation of base sediment.

Our agitators achieve more than optimum mixing results. They also deliver significant savings in energy costs. Lower operating speeds mean that less powerful agitators can be used, and this also shortens the stirring times. Furthermore, the need for power disruptors is avoided, which can accumulate solids and create dead zones.

All of our agitator systems are available in a full range of sizes, catering for use in laboratories to the agitators used in large storage containers. Please do get in touch with us and we shall be delighted to help you find the perfect solution for your requirements.

Paints & Coatings Gentle and homogeneous for a radiant lustre

The paints & coatings industry faces numerous challenges in the manufacture of its huge variety of products, including vehicle paints, hardeners and primers. Our miseco® agitators are specifically designed and built to meet these requirements. In the automotive industry, miseco® agitators are in very widespread use. The key thing here is to stir paints and coatings at a low circumferential speed to achieve smooth and uniform mixing, also for water-soluble, thixotropic products. Our agitator products ensure that the entire contents of a container get mixed smoothly and evenly without causing the product to splash.

Our stirrer system offers additional advantages for explosion-proof agitators in addition to stand solutions and container agitators for standard receptacles such as containers and buckets. Simple seals can be used because of the low rotational speeds. Our agitator systems can also be used for continuous stirring in pass-through mode. In addition, only a bottom-level stirring stage is required here to prevent splashing.

Our surface-mounted agitators are approved for Zone 0 in the tank and Zone 1 / Zone 2 in the surrounding area. Our container and stand mixers are approved for Zone 1 / Zone 2 environments. Extension agitators, container agitators and stand agitators can be used in this sector. It is quick and easy to get in touch with us, and we shall be delighted to advise you.

Pharmaceuticals & Cosmetics Hygiene and diligence to achieve great quality

The requirements governing agitator systems in the demanding worlds of the pharmaceuticals and cosmetics industries are very stringent indeed. At miseco, we rise to meet these challenges with our specially designed agitator systems. These feature ground surfaces and we manufacture them from many different materials. If required, we can also provide seal systems to suit your precise needs, including mechanical seals.

The FDA-compliant version of our agitator systems assures compliance with the specifications governing pharmaceutical and cosmetic products. Cleaning and maintenance are made easier by dispensing with the need for baffles and by the scope for removing the agitator components.

Products in this sector often require gentle, homogeneous stirring – avoiding the ingress of air and foaming action. Our innovative oscillating product flow technology enables additives to be mixed homogeneously and very rapidly indeed into the product from above. To assure optimum quality standards, our miseco agitator systems do not shear or heat your products.

Top-mounted agitators, container agitators and stand agitators can be used for a wide range of applications in the pharmaceutical and cosmetics industries. Get in touch to enables us to find a suitable solution for your requirements.

Chemicals & Plastics Adaptability to suit a huge variety of requirements

The chemical and plastics industries present a wide and diverse range of requirements for agitator systems. Es sind verträgliche Werkstoffe oder hochsensible Abdichtungen wie Gleitringdichtungen erforderlich. Here at miseco, we provide made-to-measure solutions that can be adapted to suit the individual needs and requirements of our customers.

Moreover, ex-protected agitators are essential in a few sectors. Here, our systems have additional benefits to offer: simple seals can be used because of low rotational speeds. Our agitator systems can also be used for continuous stirring in pass-through mode. In addition, only a bottom-level stirring stage is required here to prevent splashing.

Our agitator systems deliver dynamic flow conditions, keeping all the medium in motion and preventing blind spots and deposits. Our agitator systems can be used in tanks ranging from small to large, as well as in very tall ones. The miseco® disc agitator ranges offers diameters of 60 mm to 5000 mm. Moreover, our solutions can be adapted to suit specific temperatures and products.

Our surface-mounted agitators are approved for Zone 0 in the tank and Zone 1 / Zone 2 in the surrounding area. Our container and stand mixers are also approved for Zone 1 / Zone 2 environments. Contact us to identify the right solution to suit your specific needs.

Our customers around the world

These companies listen to and place their confidence in miseco.

Please contact us with any questions you may have about projects that have already been implemented:

Phone.: +49 (0) 7702/60897-0

Contact